3D printing technologyhas come a long way since its inception. Such a remarkable way to persuade scientists to affirm that living human body parts can be printed in 3Dand a real step forward in the field of regenerative medicine. In order to verify the quality of the work performed, it has already produced sections of bone, cartilage, and muscles that worked correctly when they were implanted in animals, like mice.

Producing "spare parts" for the human body? It should be possible, problably in the future. Just like the mythical Frankenstein by Mary Shelley or by the funny Mel Brooks movie.

Enough to have one hand produced by a special 3D printer, such as the one developed by the pioneer of regenerative medicine Anthony Atala, in the laboratories of Wake Forest Baptist Medical Center in Winston-Salem, North Carolina.

The research

This particular goal anticipates the moment when the medicine will be able to ensure that living tissue can be used to repair the body -- a kind of healing factor, if you want to consider in such a way.

This technology has been described by experts as "really a goose that can lay golden eggs." In fact, imagine that researchers could organize individual human cells precisely, so as to replace a damaged jaw, an ear, or a damaged heart.

In order to ensure that the products remain in tissues life, it's necessary to produce oxygen sustenance and nutrients in tissues that are thicker than 0.2 millimeters.

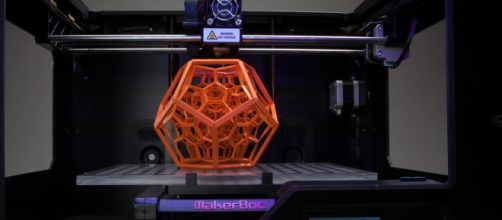

The Integrated Tissue and Organ Printing System, or ITOP, is able to deposit biodegradable plastic material that forms the outer shell of a tissue structure, as well as cellular Hydrogels, containing substances suitable to promote cell growth.

Following implantation in a living animal, in particular mice, the plastic is destroyed, being replaced with the natural process. Afterwards, the blood vessels and the nerves grow in the plant. The procedure has already provided excellent results, but tests are still needed before this technology can be used by the masses.